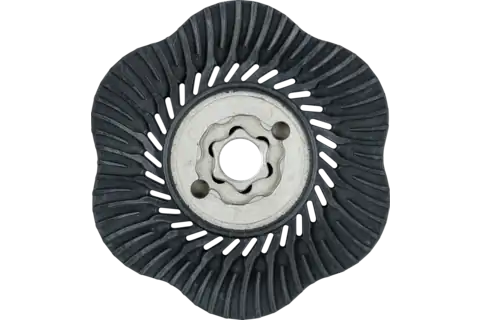

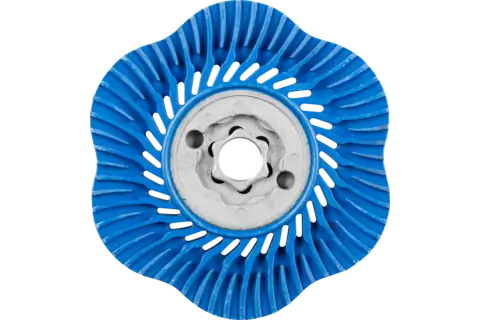

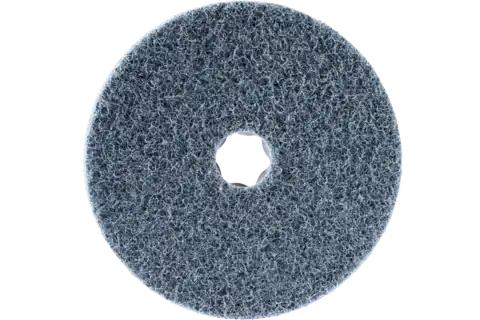

COMBICLICK® non-woven surface conditioning, hard discs

COMBICLICK® Surface Conditioning Disc Hard, 5″, 240 Grit Fine, Aluminum Oxide

Matching accessories & spare parts

Technical information

COMBICLICK® Surface Conditioning Disc Hard, 5″, 240 Grit Fine, Aluminum Oxide

- Item number

Global part number - 42000060

- Abrasive

- Aluminum oxide A

- Dia. external

- 5 Inch

- EDP no.

- 48113

- Grit size

- 240 F

- Max. RPM

- 9650 RPM

- RPM, optimum

- 3100 RPM

- Version

- fine, blue

- Packaging unit

- 10 pieces

Description

Advantages

Recommendations for use

Ordering notes

Safety notes

- Workpiece materials

- Applications

- Compatible power tools

PFERD TOOLS VALUE