Technical information

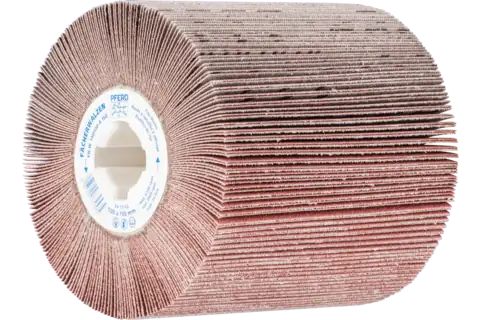

Flap Drum, 4″ x 4, 3/4″ Keyed Arbor, 150 Grit, Aluminum oxide

- Item number

Global part number - 44783150

- Abrasive

- Aluminum oxide A

- Dia. external

- 4 Inch

- Dia. hole

- 3/4 Inch

- EDP no.

- 45784

- Grit size

- 150

- Max. RPM

- 6100 RPM

- RPM, optimum

- 3800 RPM

- Width

- 4 Inch

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

Ordering notes

Safety notes

- Workpiece materials

- Applications

- Compatible power tools