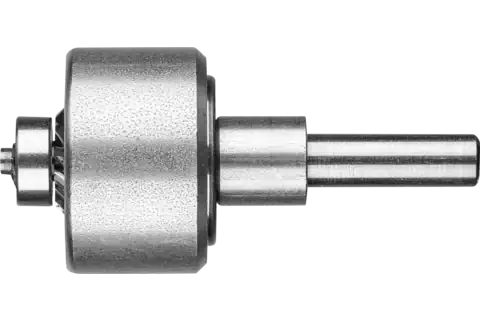

High-performance tungsten carbide burs, EDGE cut, Conical counterbore - Shape K

Bearing Carbide Bur SK-6 EDGE Cut 45° 5/8″ x 1/8″, 1/4

Technical information

Bearing Carbide Bur SK-6 EDGE Cut 45° 5/8″ x 1/8″, 1/4

- Item number

Global part number - 21725177

- Angle

- 90 °

- Cut

- EDGE ALU

- Dia. ball bearing

- 3/8 Inch

- Dia. external

- 5/8 Inch

- Dia. shank

- 1/4 Inch

- Dia. shank

- 6.35 mm

- Dia. sleeve

- 1 Inch

- EDP no.

- 25177

- Length, construction

- 9/16 Inch

- Length, cut

- 1/32 Inch

- Overall length

- 2-3/64 Inch

- RPM, hard non-ferrous metals

- 12000 - 22000 RPM

- RPM, soft non-ferrous metals

- 18000 - 22000 RPM

- SCTI-No.

- SK-6

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Ordering notes

- Workpiece materials

- Applications

- Compatible power tools

PFERD TOOLS VALUE