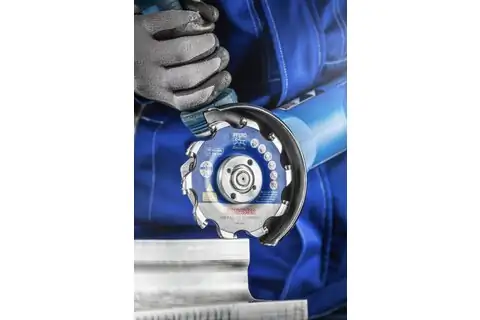

Milling tools with ALUMASTER cutting inserts, HSD-R design for radial applications

ALUMASTER High Speed Disc 4-1/2″/5

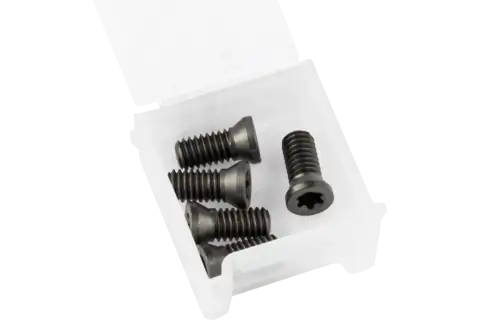

Matching accessories & spare parts

Technical information

ALUMASTER High Speed Disc 4-1/2″/5

- Item number

Global part number - 22000019

- Dia. external

- 4-1/2 Inch

- Dia. hole

- 7/8 Inch

- EDP no.

- 20100

- RPM, soft non-ferrous metals

- 13300 RPM

- Width

- 5/16 Inch

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Safety notes

Contents

- Workpiece materials

- Applications

- Compatible power tools

PFERD TOOLS VALUE