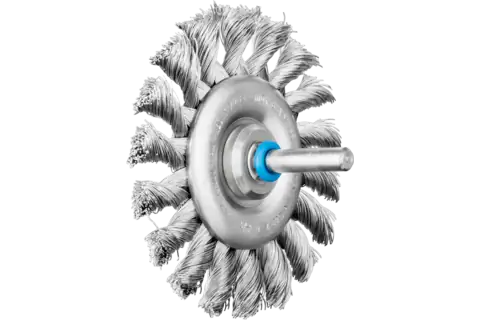

Wheel brushes knotted, INOX-TOTAL, shank-mounted

INOX-TOTAL Knot Wire Wheel Brush 3" Dia. .012 SS 6 mm Arbor

Technical information

INOX-TOTAL Knot Wire Wheel Brush 3" Dia. .012 SS 6 mm Arbor

- Item number

Global part number - 43100252

- Dia. external

- 3 Inch

- Dia. filament material

- .014 Inch

- Dia. shank

- 1/4 Inch

- Dia. shank

- 6 mm

- EDP no.

- 82743

- Filament material

- Stainless steel wire (INOX)

- Max. RPM

- 25000 RPM

- Mounting system

- Shank

- Number, knots

- 18 pcs.

- Overall length

- 1-21/32 Inch

- Packaging

- Industrial packaging

- RPM, optimum

- 10000 - 16300 RPM

- Trim length

- 3/4 Inch

- Width

- 1/4 Inch

- Packaging unit

- 10 pieces

Description

Special features

Recommendations for use

Safety notes

- Workpiece materials

- Applications

- Compatible power tools