COMPOSITE brushes

Always get the best results

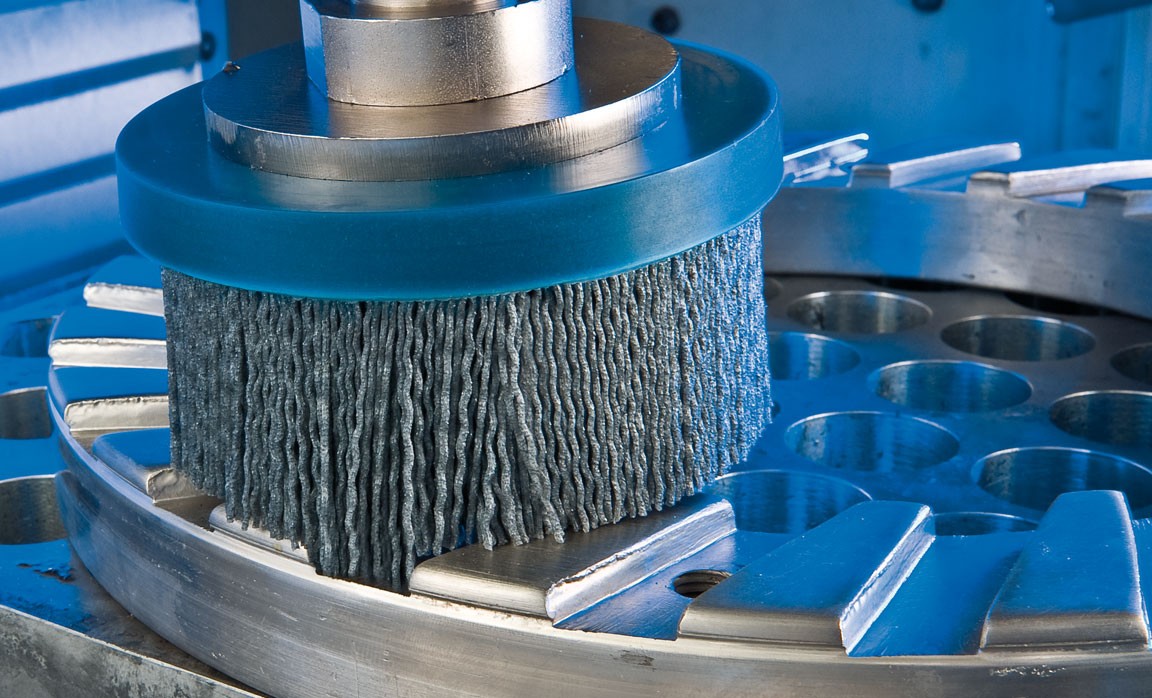

Composite brushes from PFERD TOOLS have been specifically developed for industrial, automated use. They are suitable for a variety of applications and their variable clamping options mean that they can be used on many different drive systems. This offers the advantage that the workpiece can be produced and finished on the same machine. As a result, labour-intensive, manual work is reduced and reproducible results are achieved with short cycle times.

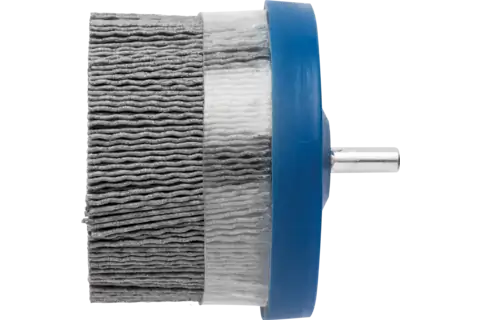

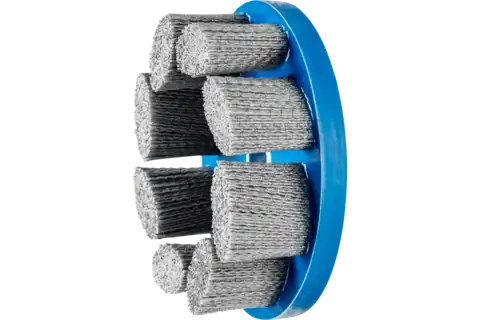

The standard type of composite brushes is suitable for tasks requiring aggressive brushing behaviour. The FLEX type is more flexible than the standard type due to its longer trim length on wheel brushes and the special arrangement of the filament on composite disc brushes, and it is particularly well suited to work on irregular surfaces.

For efficient use, numerous application parameters such as the processing time and feed rate must be coordinated with each other and a suitable brush must be selected. PFERD TOOLS offers a wide range of products for the various applications. Our experienced sales representatives and technical advisers will be happy to help or visit you.

Advantages:

- Long tool life and aggressive brushing effect due to a very high filament density.

- Extremely smooth operation due to even distribution of the filament material.

Filament material – plastic filament

Abrasive grains are embedded in flexible plastic filaments, which means that the filament works on the sides as well as at the tip.

- Silicon carbide (SiC): particularly well suited to deburring work and for improving surfaces.

- Ceramic oxide grain (CO): offers good toughness and excellent sharpness. For high stock removal and aggressive brushing.

- Round filament: for applications that place particular demands on the flexibility of the brush.

- Rectangular filament (REC): for applications that place particular demands on the aggressiveness of the brush.

Extensive range for different applications

Composite brushes from PFERD TOOLS are available in a wide range of filament types and configurations. The standard type is suitable for tasks requiring aggressive brushing behaviour. The FLEX type is more flexible than the standard type due to its longer trim length on wheel brushes and the special arrangement of the filament on composite disc brushes, and it is particularly well suited to work on irregular surfaces.