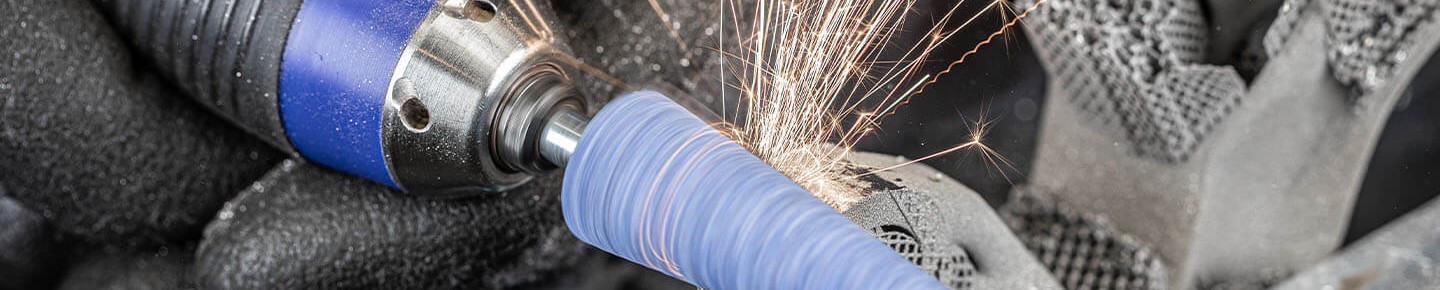

TOUGH mounted points

For universal use on materials that are difficult to machine

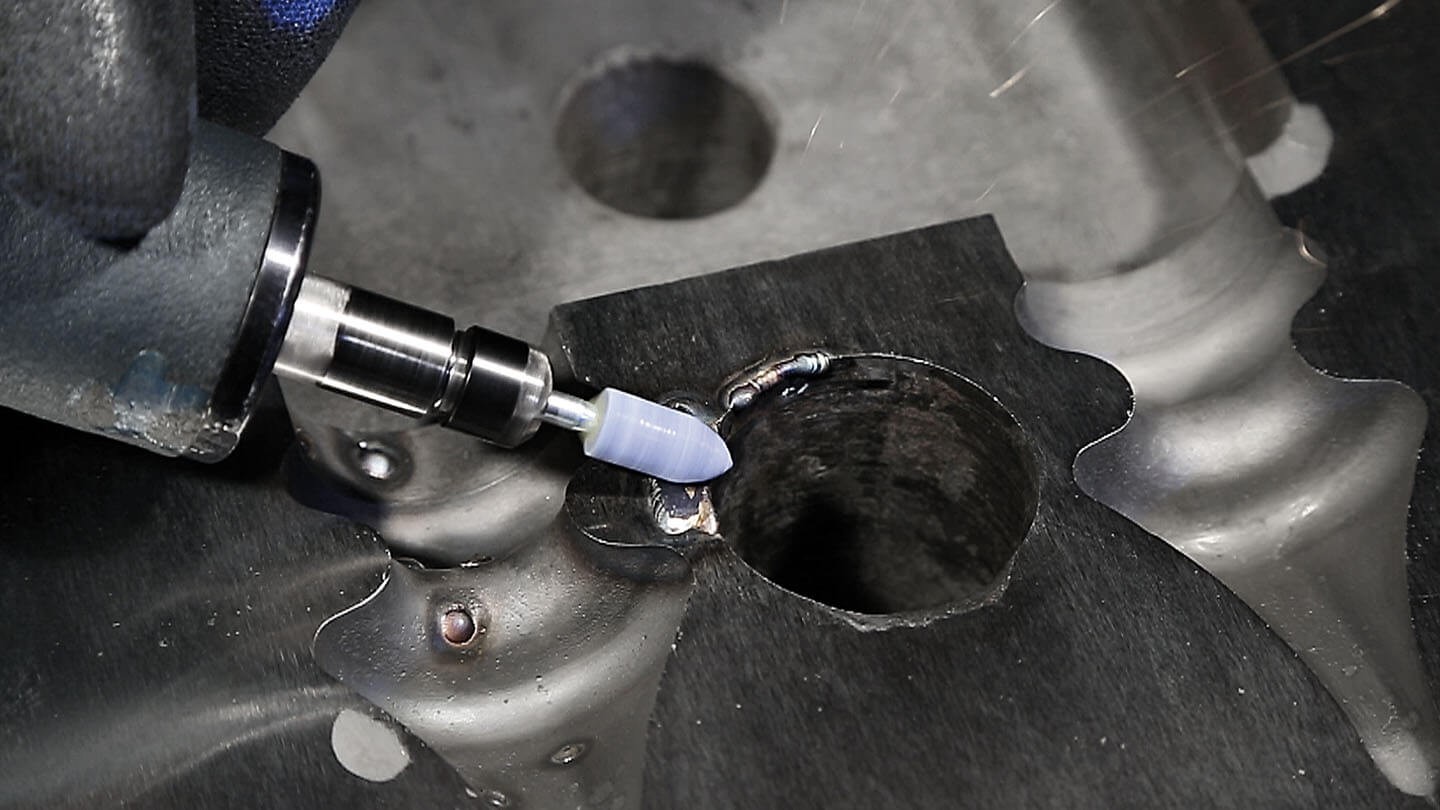

The TOUGH type is specifically designed for use on titanium materials, nickel-based and cobalt-based alloys, hardened steel components and built-up weld deposits. Its applications include weld dressing on repair welds and reworking on turbine blades during aircraft maintenance, as well as regrinding of repair welds in tool and mould-making.

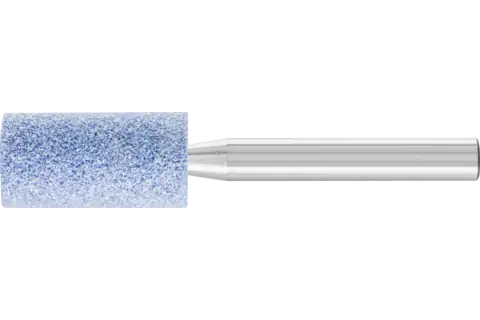

TOUGH-type mounted points consist of a vitrified bond with an aluminium oxide mixture of ceramic oxide grain and white aluminium oxide.

Advantages:

- Cool grinding as the grain mixture is easy to break down.

- High stock removal rates and very good tool life.

- Constant stock removal rates thanks to the self-sharpening qualities of the ceramic oxide grain.

Materials:

- Hardened, heat-treated steels over 1,200 N/mm² (> 38 HRC)

- Titanium alloys

- Titanium

- High-temperature-resistant materials

- Nickel-based and cobalt-based alloys

Application tips

- TOUGH mounted points perform best at a cutting speed of 30 to 50 m/s.

- Mounted points should be used with a flexible shaft drive or a straight grinder.

- TOUGH mounted points are used for tool and mould-making as well as engine and turbine construction.

- TOUGH mounted points should be used with an adjusted contact pressure.

- Use dressing stones for profiling and dressing.

- Use coarse grit sizes for stock removal and rough grinding. Use fine grit sizes for fine grinding.

PFERD TOOLS VALUE: