Filing: the most important principles

Chamfering, deburring, roughing, finishing, sharpening, removing and reworking: file applications are as varied as their shapes. For more than 200 years, PFERD TOOLS files have been manufactured in a world-renowned high quality. The experience gained over many years as a tool manufacturer is constantly used for the development of PFERD TOOLS files.

What is the basic structure of a file?

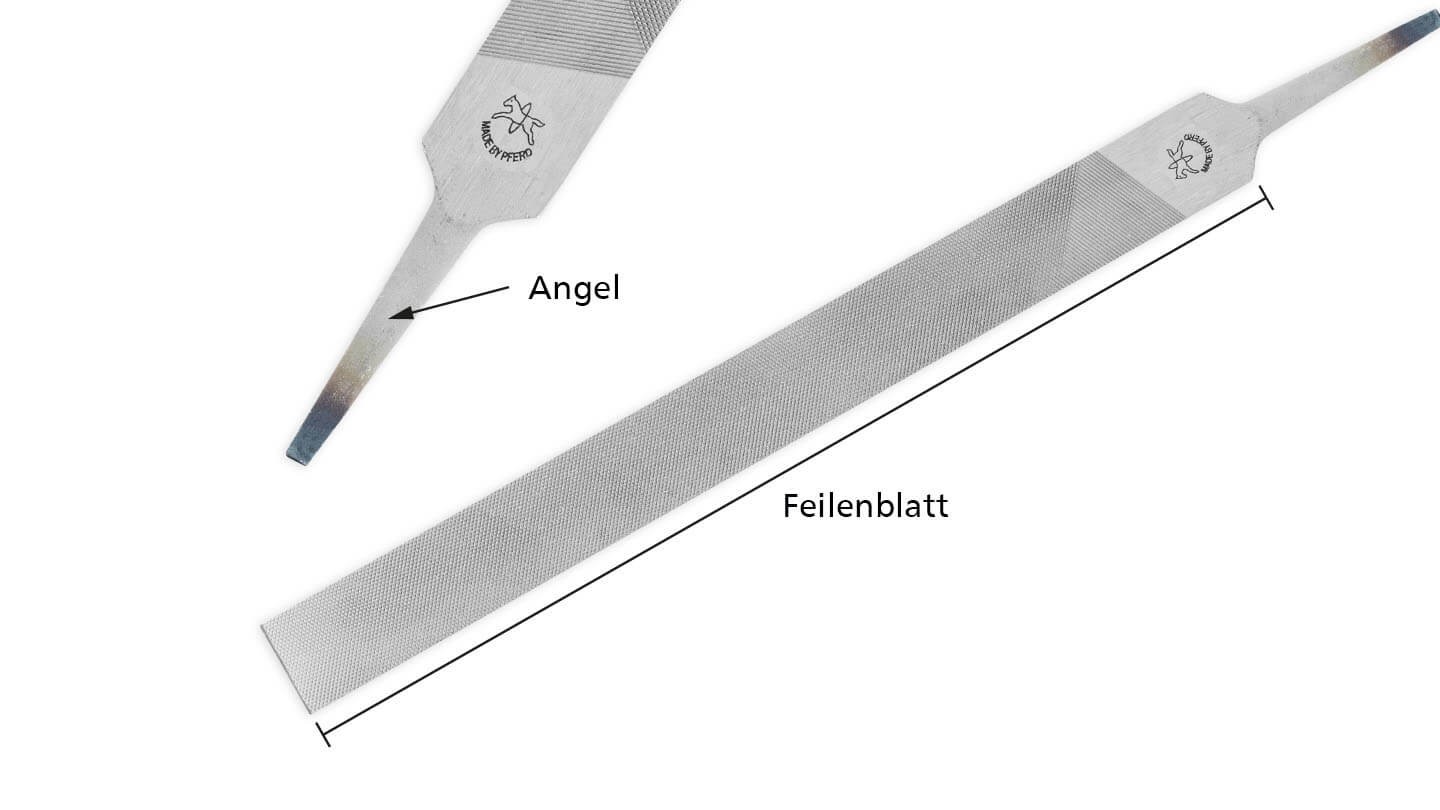

A file is a manually guided stock removal tool that usually consists of a file blade and a file tang.

A cut or tooth is added to the file blade, determining its later intended use. The tang accepts the file handle. Sometime, a handle can replace the tang.

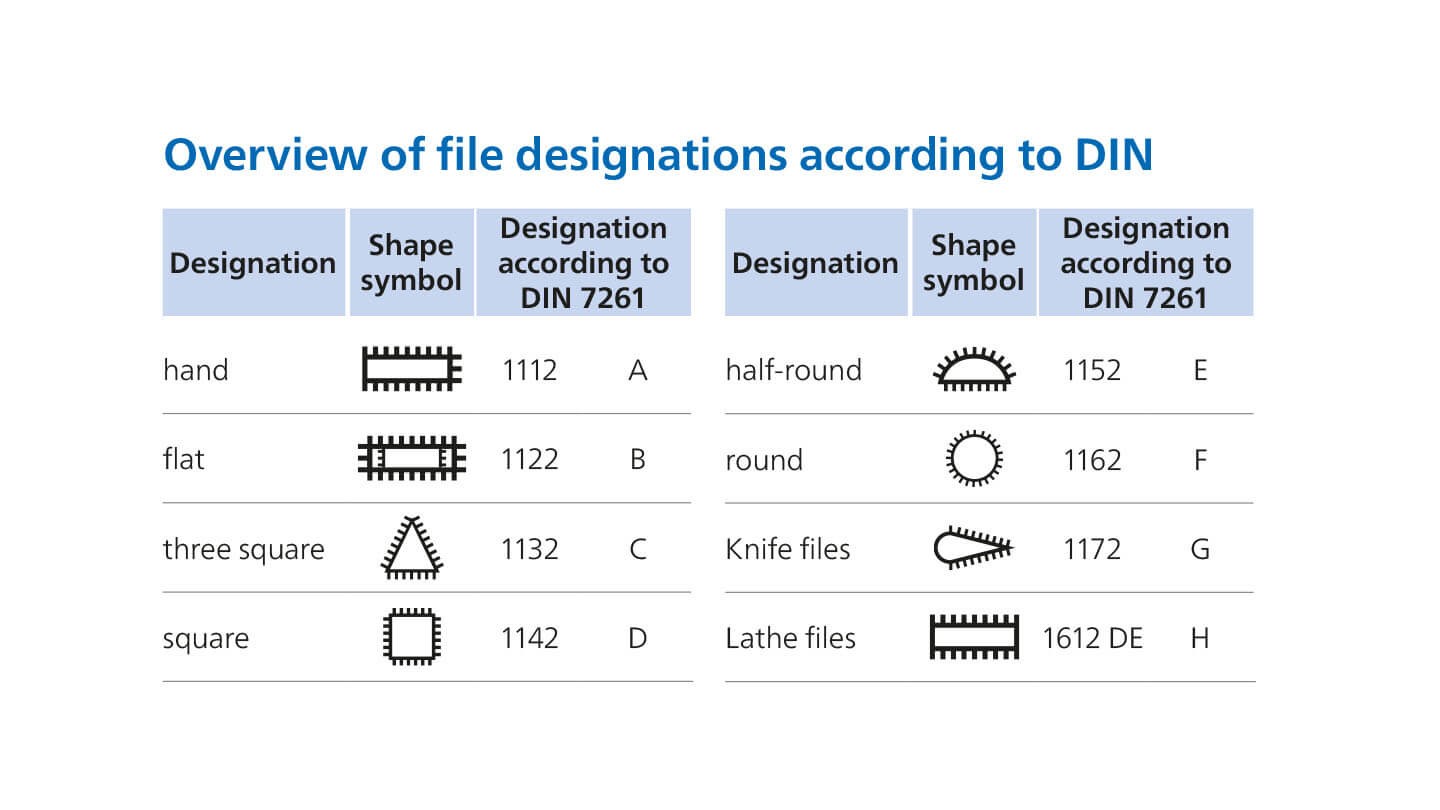

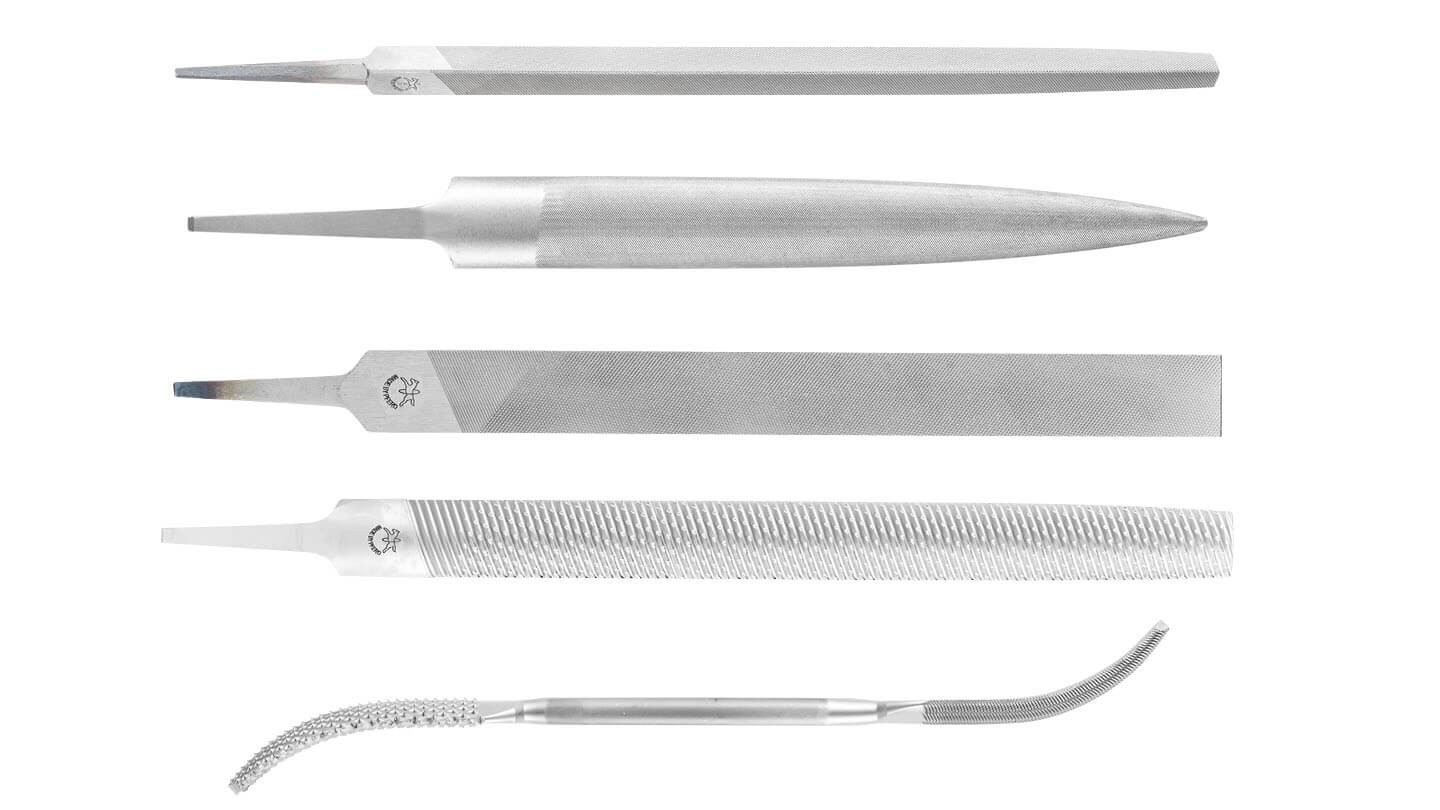

What are the typical file profiles?

The designations for file profiles are specified in DIN 7261. You will find an overview of them in the following slide show:

Cut and tooth: What is the difference?

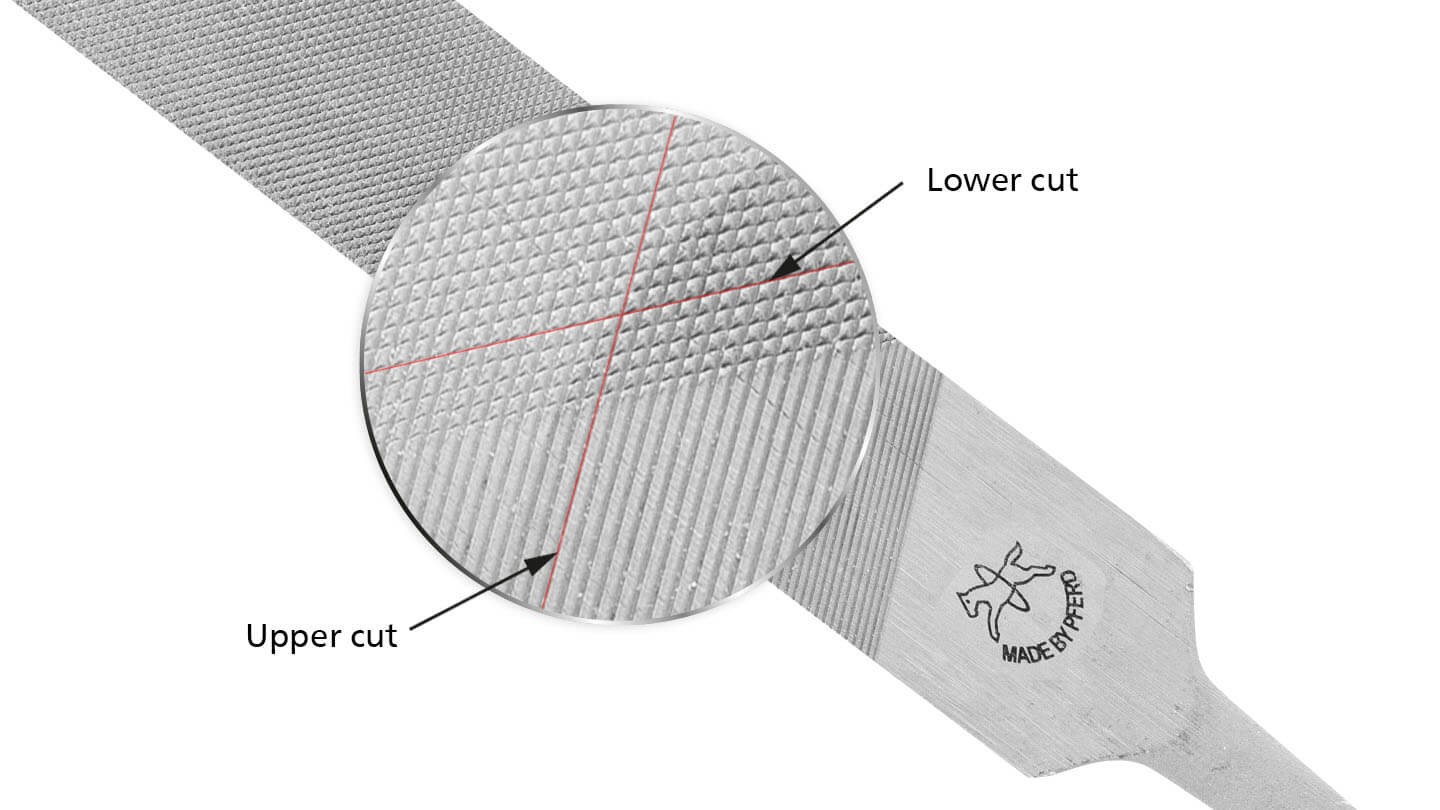

Cut is the designation for the number of scores cut into the file blade. A distinction is made between single cut, cross cut and rasp cut. In the case of cross cut, the lower cut and then the upper cut is created, yielding a cross pattern.

The type of cut is specified using numbers. The rule is: the higher the number, the finer the cut.

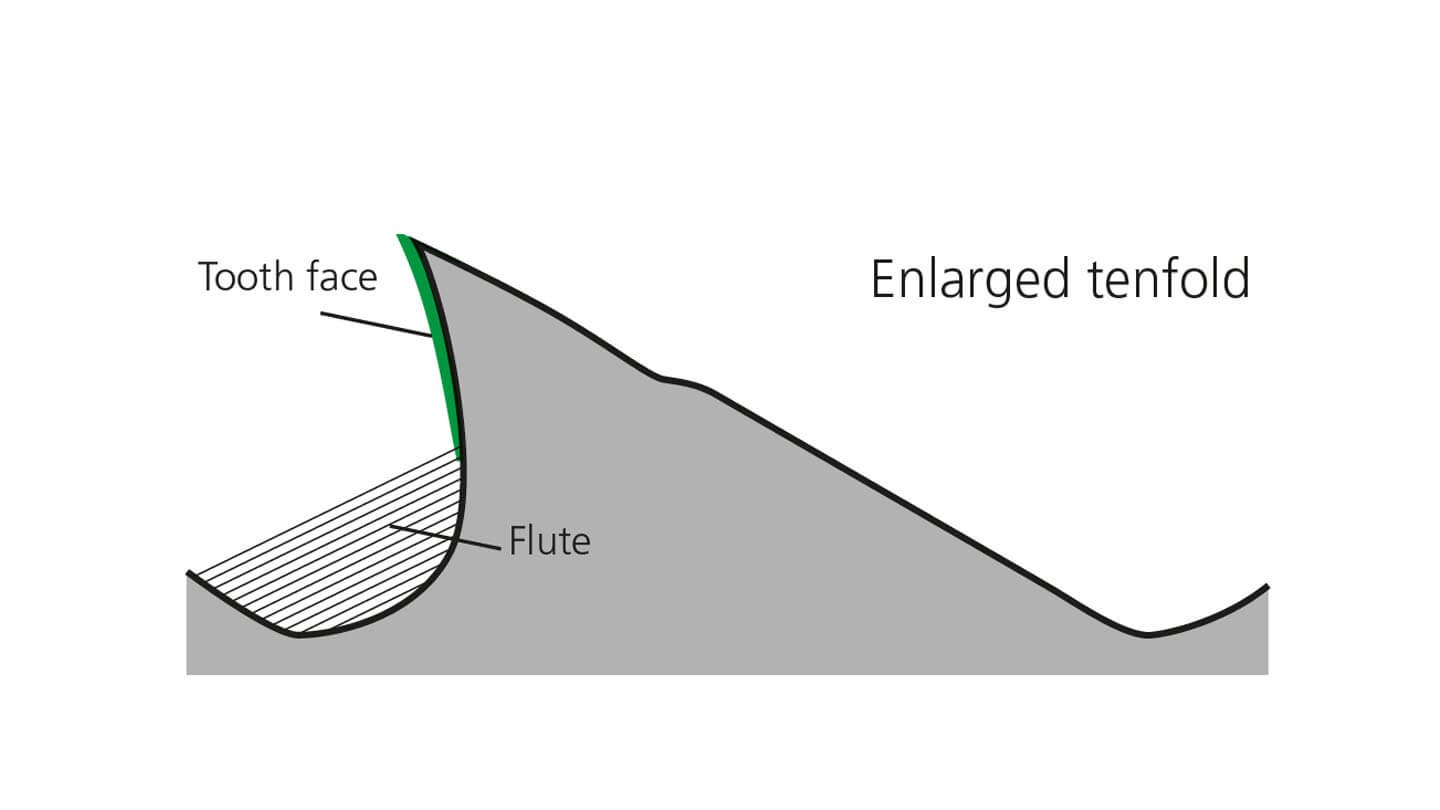

Unlike cut files, the teeth of milled files are milled from solid material. Each individual tooth is designed to ensure that the chip rolls up in front of the rounded tooth face and can be contained in the large flute.

How is the number of teeth determined?

The number of teeth for a file is the number of scores (cuts) per cm of file length. They are counted in the direction of the file axis. For cross cut files, the number of teeth is determined based on the upper cut.

Example: At a length of 250 mm, a cut 1 file has 9 teeth/1 cm of file length. A 100 mm long cut 1 file has 17 teeth/1 cm of file length, however. The higher number of teeth on shorter files ensures the same ease of use (in terms of force input, guidability and stock removal rate) on surfaces and edges as for longer files.

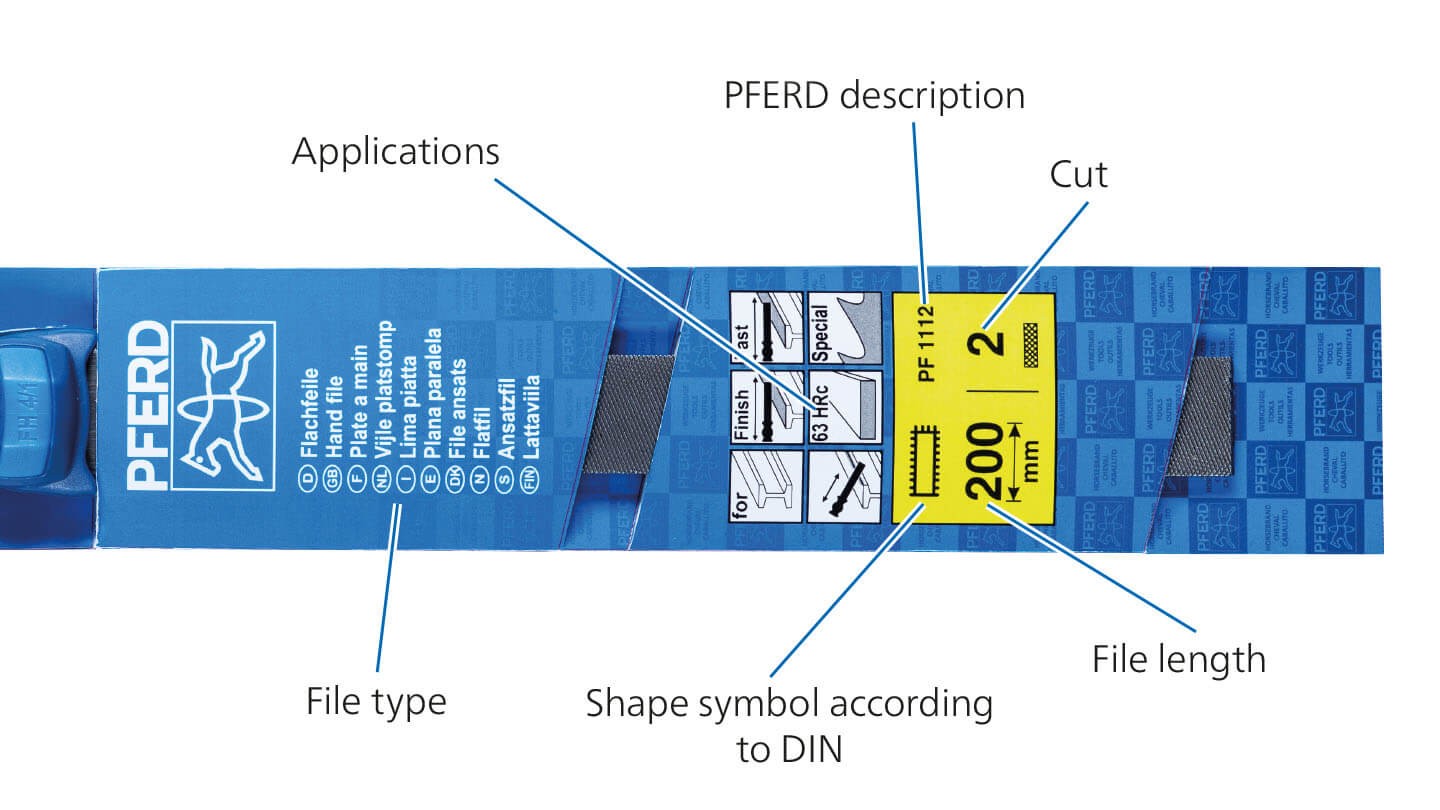

Product marking on PFERD TOOLS packaging

On the special PFERD TOOLS point-of-sale packaging, you will find the key information on your file tool:

The different colours used for the cuts available facilitate fast tool selection:

Which factors determine PFERD TOOLS quality?

Application-oriented file shapes and cuts for industry and the trades ensure good economic value. Even after long use, PFERD TOOLS files achieve high stock removal rates and an excellent surface quality. State-of-the-art production technology and strict quality controls guarantee the outstanding PFERD TOOLS quality.

The key quality criteria:

- Uniform hardness through flawless steel microstructure.

- Exact shape and uniform cut from tang to tip.

- Perfectly milled tooth geometries for every application.