Prevent Delamination

Press release - 03/05/2025

Due to their attractive properties, composites are increasingly replacing traditional materials such as aluminum and steel in the aircraft construction industry – yet machining and maintenance continue to present major challenges for providers, particularly in terms of material fraying.

In aircraft construction, composites are being used more frequently because they offer numerous advantages over traditional materials such as aluminum and steel. In addition to reduced weight, they stand out with their high strength, rigidity and corrosion resistance. Composites also offer excellent design flexibility, as they can be turned into complex shapes that would be difficult to achieve with metal. They also help to reduce vibration and noise while simplifying aircraft maintenance, as fewer parts are susceptible to wear or corrosion.

Composites are used in many different areas, especially where weight savings and high strength are crucial factors. Primary areas of use include the fuselage, wings, empennage and cowling. Increasingly, however, composites are also found on internal structures and components, such as those in the cockpit and cabin, on floor structures and on landing gear components.

Due to their attractive properties, the use of these materials is contributing to the efficiency, performance and durability of modern aircraft. As a result, composites are increasingly replacing traditional metal materials in the aircraft construction industry, though they are unlikely to replace them entirely. There are four key issues that are currently preventing this:

1. Costs: Composites are currently still more expensive to manufacture than metal parts. Although costs are falling as technologies are advancing, they remain a factor.

2. Proven technology: Metals such as aluminum and titanium have proven themselves over decades and are still the trusted option when it comes to reliability and safety. The demand for metal materials remains high, particularly for safety-critical components.

3. Recycling: Compared with metals, recycling composites is more complicated and more expensive. This is an area where metal materials are still superior.

4. Difficulties with machining, repair and maintenance: Compared with metals, composites are more difficult to repair. Damage to composites, such as delamination (the separation of layers), can be hard to identify and requires specialized techniques and knowledge to repair.

When it comes to machining, repair and maintenance, new techniques and tools are making this work easier and reducing problems during application. Germany-based tool manufacturer PFERD Tools has been focusing on application topics in the aerospace industry for many years and the growing significance of composites such as CRP and GRP has led it to find solutions, as developer Nicolas Huth confirms: “We have worked very closely with users in the field of composite machining, both with regard to the manufacture of new parts and for classic repair applications.” Huth explains that this cooperation has enabled them to learn “above all what matters to companies when faced with these problems.”

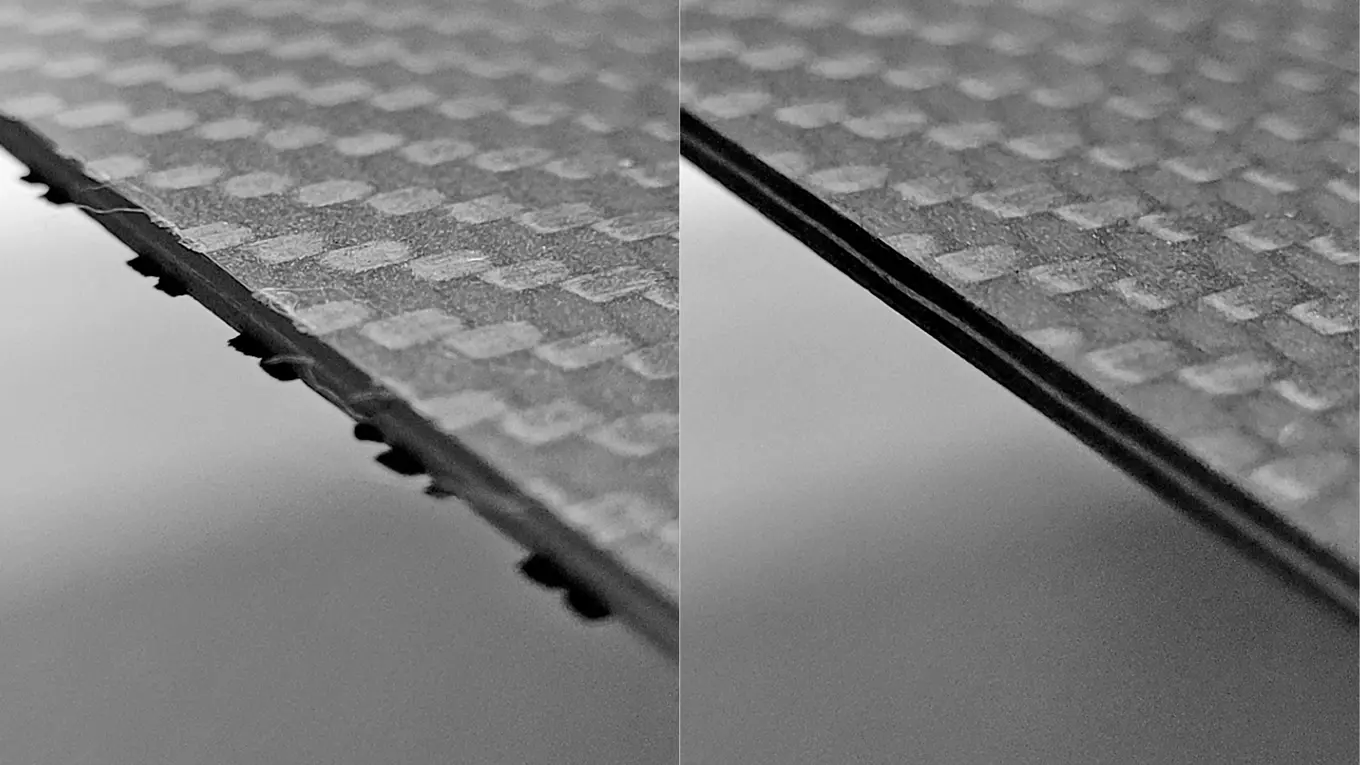

One of the solutions that has arisen from this collaboration is the solid tungsten carbide end mill for stationary machines. “What is known as the FRP cut allows components made of CRP and GRP to be trimmed, holes to be cut out, and grooves and pockets to be milled. The FRP cut results in high performance, smoother operation and low delamination and fraying. In addition, it minimizes vibrations,” the developer explains. “The powerful HICOAT diamond coating not only enables significantly increased tool life for the end mill but also provides consistent cutting performance with a sharpening effect. This keeps the cutting behavior constant and the cutting edge radius even, to the greatest possible extent.”

The end mills are used on both robots and stationary production plants. “We have been able to gain extensive experience with companies operating in the industry and also able to help find solutions here,” adds Nicolas Huth.

About PFERD

August Rüggeberg GmbH & Co. KG – PFERD Tools (www.pferd.com) is among the leading companies that manufacture tools for work on surfaces and metal cutting. With a heritage that dates back more than 220 years, the family-run business, based in Marienheide, manufactures its products across seven different production facilities and its current portfolio includes over 9,500 tools.

Press contact

PFERD North America

Elizabeth McKusick

E-Commerce & Marketing Manager

9201 W. Heather Ave

Milwaukee, WI 53224

Office: 262-345-1992

E-mail: elizabeth.mckusick@pferd.com – us.pferd.com

Image(s) © August Rüggeberg GmbH & Co. KG