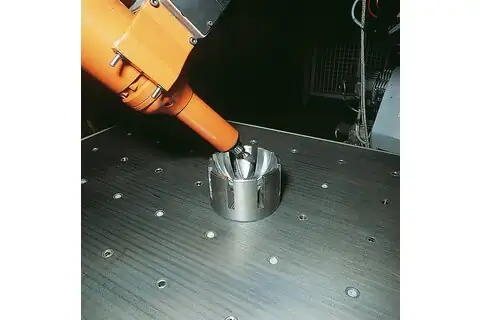

Tungsten carbide burs for versatile use, Double cut, 14° Taper bur with radius end – Shape L

Carbide Bur SL-3 14° Taper Double Cut 3/8" x 1-1/16" x 1/4" Shank

Technical information

Carbide Bur SL-3 14° Taper Double Cut 3/8" x 1-1/16" x 1/4" Shank

- Item number

Global part number - 21725152

- Angle

- 14 °

- Cut

- Double

- Dia. external

- 3/8 Inch

- Dia. shank

- 1/4 Inch

- EDP no.

- 25152

- Length, cut

- 1-1/16 Inch

- Overall length

- 3 Inch

- RPM, grey cast iron, white cast iron

- 14.000 - 19.000 RPM

- RPM, hard non-ferrous metals

- 8.000 - 11.000 RPM

- RPM, hardened, heat-treated steels over 370 HV (38 HRC)

- 8.000 - 11.000 RPM

- RPM, high-temperature-resistant materials

- 8.000 - 14.000 RPM

- RPM, rust and acid-resistant steels

- 8.000 - 11.000 RPM

- RPM, soft non-ferrous metals

- RPM

- RPM, steels up to 370 HV (38 HRC)

- 14.000 - 19.000 RPM

- Radius corner design

- 0.114 Inch

- SCTI-No.

- SL-3

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

- Workpiece materials

- Applications

- Compatible power tools