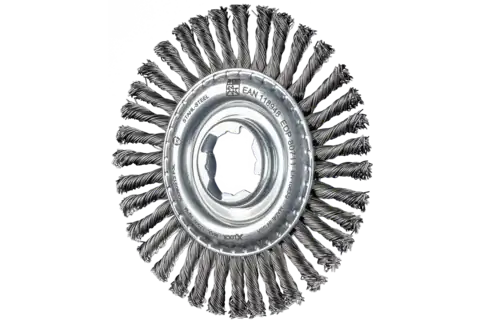

Wheel brushes, knotted, pipeline

PIPELINE brush knotted RBG dia. 100x6 hole 22.2 mm/X-LOCK stainless steel wire dia. 0.50 mm angle grinders

Technical information

PIPELINE brush knotted RBG dia. 100x6 hole 22.2 mm/X-LOCK stainless steel wire dia. 0.50 mm angle grinders

- Item number

Global part number - 79180425

- Dia. external

- 4 Inch

- Dia. filament material

- .020 Inch

- Dia. hole

- 7/8 Inch

- Dia. thread

- X-LOCK

- EDP no.

- 80425

- Filament material

- Stainless steel wire (INOX)

- Max. RPM

- 20000 RPM

- Mounting system

- X-LOCK

- Number, knots

- 32 pcs.

- Packaging

- POS packaging

- RPM, optimum

- 8.000 - 15.000 RPM

- Trim length

- 3/4 Inch

- Width

- 3/16 Inch

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

- Workpiece materials

- Applications

- Compatible power tools

PFERD TOOLS VALUE